For ripening, we offer several solutions: the stacker, the unstacker and the flipper.

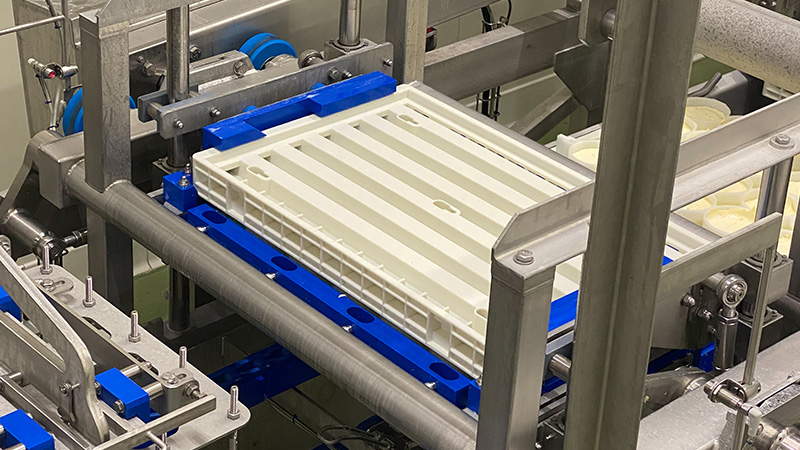

Stacker and unstacker

The strenghts of the stacker and unstracker:

- Hygienic design: open profile,

- Soft handling of dishes,

- Simplified maintenance,

- Compliance with safety standards,

- Programmable stack height management,

- No mechanical elements above the product,

- Rapid rate: 5 seconds per tray,

- Management of the base foot in automatic.

Stack flipper

The strengths of the stacks flipper:

- Hygienic design,

- Height of the returnable stacks is adjustable,

- Simplified maintenance,

- The flipper can be separated from the draining or integrated of the fully automatic draining.

Individual turning

Individual turning:

- Hygienic design,

- Simplified maintenance,

- High rate: 700 trays per hour,

- Eliminate the cap phenomenon on the cheese,

- Suitable for large diameter cheeses.

Turning by cartesian robot

Turning by cartesian robot:

- 3 functions with one machine: stacking, destacking, unit turning,

- Small footprint: one machine to do 3 functions,

- High rate: 6 seconds per tray.